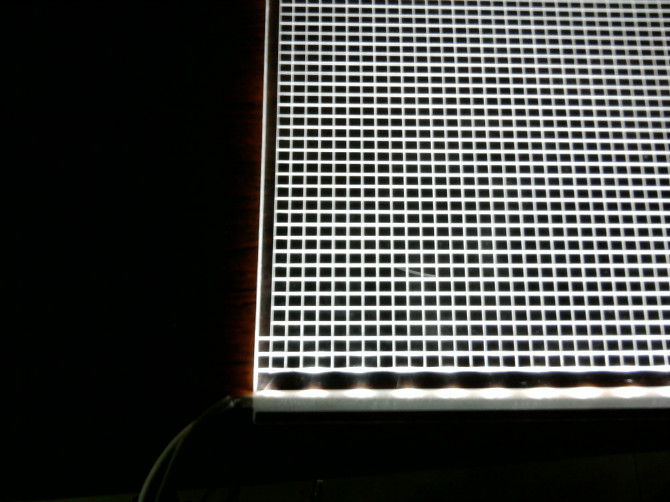

The 3D V-cutting technology means that the acrylic light panel V grooves have x, y and -axis dimensions. In other words, 3D V-cutting enlarges horizontal V grooves and vertical V grooves. The vertical V grooves are widely spaced when they are closed to the light source, but narrowly spaced when farther away from the light source. An enlarged horizontal V groove is arranged in a straight line along an x-axis direction from one end side of the acrylic light panel and has a maximum enlarged portion located on the other side end of the acrylic light panel.

The 3D V-cutting technology means that the acrylic light panel V grooves have x, y and -axis dimensions. In other words, 3D V-cutting enlarges horizontal V grooves and vertical V grooves. The vertical V grooves are widely spaced when they are closed to the light source, but narrowly spaced when farther away from the light source. An enlarged horizontal V groove is arranged in a straight line along an x-axis direction from one end side of the acrylic light panel and has a maximum enlarged portion located on the other side end of the acrylic light panel.

3D V-cutting technology ensures that the acrylic light panel is brighter than any printed panel and illumination is uniform throughout surface of the acrylic light panel.