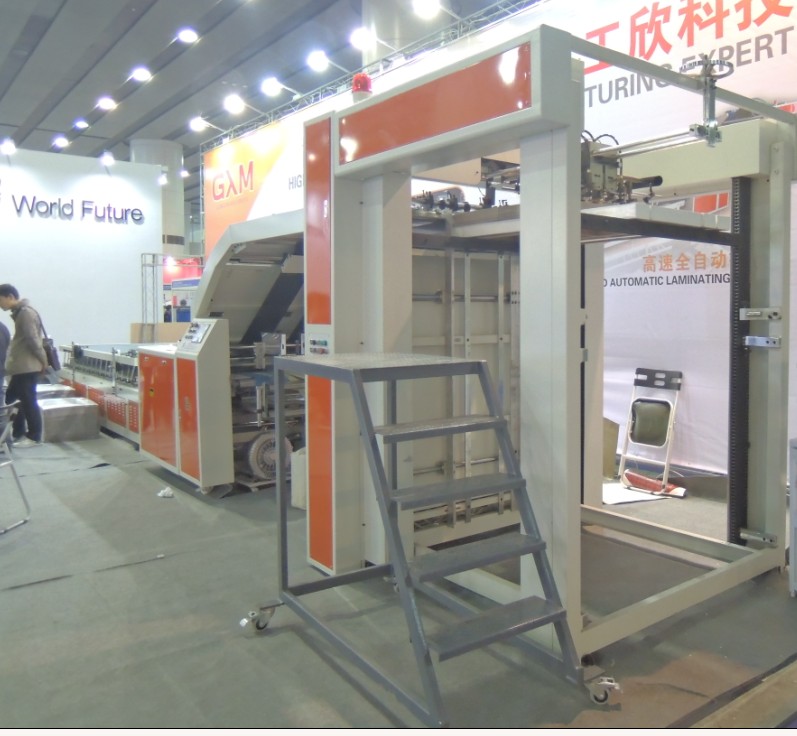

High speed all automatic laminating machine improved the automatic up and down surface paper[paper?:paper sample maker cutting machine] system. Surface paper can pile up the height of 1m once time, using photoelectric automatic up. So this design reduced more time for moving the surface paper. And the bottom corrugated board also send automatically.

High speed all automatic laminating machine improved the automatic up and down surface paper[paper?:paper sample maker cutting machine] system. Surface paper can pile up the height of 1m once time, using photoelectric automatic up. So this design reduced more time for moving the surface paper. And the bottom corrugated board also send automatically.

Main feature of high speed all automatic laminating machine:

1. The top paper can pile up the height of 1m once time ,it makes delivery more easier and efficient

2. Using siemens PLC, Inverter, Low-voltage electrical, makes the system more stable and reliable , working is more precision and stable,improved the speed, circuit faults can automatically alarm.

3. Using suction feeding automatic of bottom sheet, according to the main machine operating speed, continuous automatic tracking

4. Entire new concept,front gauge registration, position high accuracy, bottom sheet never exceed the top sheet.

5. Machine uses touch-screen / PLC control system, the circuit system is stable, and can automatically display the failure alarm

6. The automatic replenishment system of glue can be added automatically during glue losses, and recycling with the glue to avoid loss of waste;

7. Using the rubber roller cleaning to make cleaning thoroughly, and so that the back of the corrugated cardboard never gets glue, and eliminating the trouble of frequent replacement of blade.

8. Floating removable press, to ensure that laminated paper will not be crushed, and also keep the cardboard smooth and straight; unilateral adjustment by way of adjustment worm roll lamination pressure for quick

9. Control of water tank cleaning cycle using an independent method, clean, hard rubber product;

10.Suitable for color top sheet 250-450 g and A/B/C/D/E/F corrugated paper[corrugated paper?:DCP-H series sample cutter plotter] laminating;