gasket failure reasons

1. uneven distributed pressing force, the uneven pressing force is caused by a variety of factors, first is the human factor: asymmetric construction of the preload bolt, this factor can eliminate construction; theory on the flange pressed, the sealing surface is absolutely parallel to the practice, however, the centerline of a pipeline can not be absolutely concentric, and thus tighten the bolts on the flange moment, so that the flange discontinuity. Asymmetrical connection, the sealing surface more or less deformed, so that sealed the pressing force is reduced, the running load, prone to leakage. Third, the density of bolt arrangement on the pressure distribution more obvious impact, bolts suffer the closer, the pressure is becoming more uniform.

2. Stress relaxation and torque loss: stress relaxation and the torque loss is the main cause of leakage. Tighten bolts on the flange, due to the vibration of the bodies, the temperature increased or decreased and other factors, the working process of the spiral wound gaskets stress relaxation, the bolt torque will be gradually decreased, resulting in loss of torque. cause a leak. In general, long bolts, the remnants of the torque, the smaller the diameter the more advantageous to prevent the loss of torque, with long, thin bolt is an effective way to prevent torque loss. In addition, the greater the temperature, the longer the duration, the more serious loss of torque. Heating a certain period of time to make it stretch the bolt, and then to maintain a given torque, is very effective to prevent the loss of torque. There is a

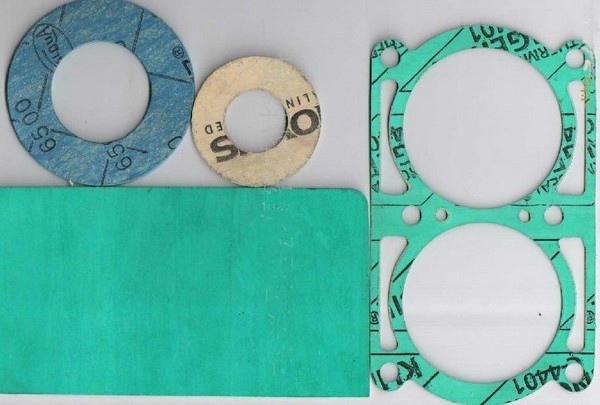

gasket[gasket?:gasket die cutting machine] is thinner and smaller the loss of torque. In addition to prevent the strong vibration of the machine and the pipe itself, and exclude the impact of adjacent equipment vibration, the impact of the sealing surface is not meaningless, not to beat the bolts tightened, can prevent the loss of torque.

3. Surface not smooth: the sealing surface finish improper also easy to cause leakage.

4. Temperature: the temperature decreases have a greater impact on the leakage. Flanged leak often occurs in the cooling, because the cooling rate of cooling when the flange and bolts do not After cooling, the pressing force of the metal gaskets stress relaxation, combined with the cold contraction of the pipe, resulting in toward the bolt tensile direction force, this force will lead to leaks in, where the low-temperature media occasions when

gasket should be noted: 1) low temperature flexible

gasket; 2) shim thickness should be as much as possible to take a small flange gap as small as possible ; 3) high strength bolts, so that the strain is small.