Printing the apparel pattern

A computer template (or plot) is used to plot out the apparel[apparel?:apparel paper cutter machine] pattern. apparel pattern pieces are laid out in such a way that little tissue will be wasted in the printing[printing?:printing cutting finishing solution] process. The computerized plot and the instruction sheets are physically sent to the printer. The pattern envelope, however, is sent to the pattern printer electronically.

A computer template (or plot) is used to plot out the apparel[apparel?:apparel paper cutter machine] pattern. apparel pattern pieces are laid out in such a way that little tissue will be wasted in the printing[printing?:printing cutting finishing solution] process. The computerized plot and the instruction sheets are physically sent to the printer. The pattern envelope, however, is sent to the pattern printer electronically.

The plot is unrolled on a pre-sensitized / aluminum plate that varies in size according to the size of the tissue sheet to be printed. Plates are as small as 30 in x 90 in (76.2 cm x 229 cm) or as large as 50 in x 90 in (127 cm x 229 cm). A vacuum frame adheres the plot to the aluminum plate, lights expose the plate, and the plate is etched where the lines on the plot are printed. Thus, the plate is essentially burned with the image of the pattern pieces.

The plate is then printed using off-set lithography. The image is inked, transferred to a felt blanket, and is then transferred from the felt blanket to paper[paper?:paper sample maker cutting machine]. This saves wear on the metal plate.

apparel pattern tissues are printed in units of 1,300 sheets. These units are kept together using clamps and are transported together. Some units may be cut down into smaller tissue pieces with a sharp saw. All tissue pieces must be folded to fit into the envelopes and may be either folded by hand or by machine. Instruction sheets are also printed using off-set lithography.

Envelopes, however, are sent electronically from the design offices. A film[film?:film cutting machine] of the envelope design is created off the computer information and is used to expose the aluminum plate. The four-color envelope

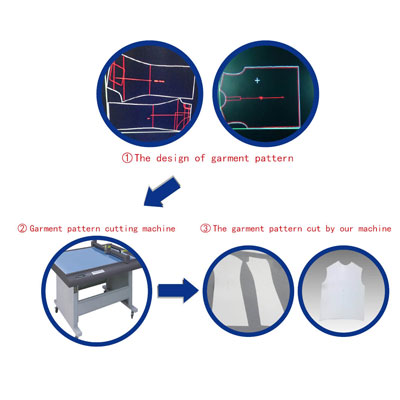

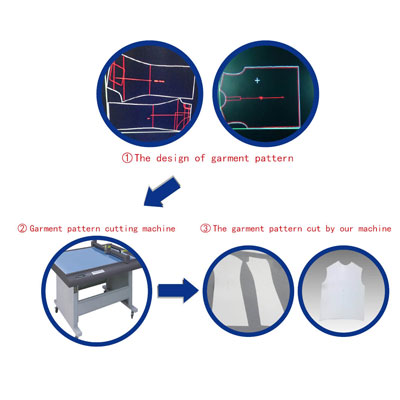

Once the apparel pattern is tested and approved, a computerized grading program creates the various size apparel patterns and the desired amount of fabric needed is measured.

is then printed with off-set lithography. Once printed, the envelopes are folded, glued, and readied to receive the folded tissue patterns.

One single apparel pattern printing facility can print[print?:printing image graphic cutting solution] 100,000 complete apparel patterns (meaning all the tissue pieces) in a single day; it produces 23 million patterns in one year.

CUTCNC[CUTCNC?:cutting machine sample maker manufacturer] offer apparel pattern cutting table[cutting table?:sample maker cutting table] can cut the paper pattern before the printing.

A computer template (or plot) is used to plot out the apparel[apparel?:apparel paper cutter machine] pattern. apparel pattern pieces are laid out in such a way that little tissue will be wasted in the printing[printing?:printing cutting finishing solution] process. The computerized plot and the instruction sheets are physically sent to the printer. The pattern envelope, however, is sent to the pattern printer electronically.

A computer template (or plot) is used to plot out the apparel[apparel?:apparel paper cutter machine] pattern. apparel pattern pieces are laid out in such a way that little tissue will be wasted in the printing[printing?:printing cutting finishing solution] process. The computerized plot and the instruction sheets are physically sent to the printer. The pattern envelope, however, is sent to the pattern printer electronically.