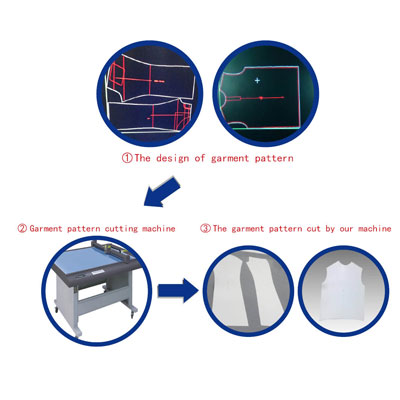

The basic procedure for apparel[apparel?:apparel paper cutter machine] making is to design a pattern and put it into an identifiable form. The traditional method of pattern making[pattern making?:pattern making] includes creationof hard paper[paper?:paper sample maker cutting machine] patterns. The modern apparel making system has adopted the digitization of pattern making process. These days many clothing[clothing?:clothing paper cutter machine] firms providethe most modern and technical services for garment[garment?:garment paper cutter machine] construction. They can create fresh computerized patterns or make modifications to existing hard paperpatterns or digitize the available data. These patterns can be made from theirown samples or specifications provided by the apparel manufacturers. Most ofthese firms try to provide patterns that will sew properly without confusion inthe production line.

The basic procedure for apparel[apparel?:apparel paper cutter machine] making is to design a pattern and put it into an identifiable form. The traditional method of pattern making[pattern making?:pattern making] includes creationof hard paper[paper?:paper sample maker cutting machine] patterns. The modern apparel making system has adopted the digitization of pattern making process. These days many clothing[clothing?:clothing paper cutter machine] firms providethe most modern and technical services for garment[garment?:garment paper cutter machine] construction. They can create fresh computerized patterns or make modifications to existing hard paperpatterns or digitize the available data. These patterns can be made from theirown samples or specifications provided by the apparel manufacturers. Most ofthese firms try to provide patterns that will sew properly without confusion inthe production line.

Grading is the process used for creating sized patterns. There are certain proportional rules and set increments that form the basis of grading. Theserules are set on the basis of analysis on body measurements of the general population. The clothing firms also help in pattern grading using thespecifications provided by the apparel manufacturers and some of them also assist the manufacturers in establishing specifications for their product. The grade rules are developed keeping in view the market segment for which theproduct is intended such as men, women, youth, child, toddler etc. These firm smostly use the softwares available in the market for checking the accuracy ofthe grades.