CAD/CAM in the footwear[footwear?:Footwear paper pattern cutter] industry is the use of computers and graphics[graphics?:graphics pattern] software for designing and grading of shoe upper patterns and, for manufacturing of cutting dies, shoe lasts and sole moulds. CAD/CAM software is a PC-based system, which is made up of program modules. Today, there are 2D and 3D versions of CAD/CAM systems in the shoe industry.

CAD/CAM in the footwear[footwear?:Footwear paper pattern cutter] industry is the use of computers and graphics[graphics?:graphics pattern] software for designing and grading of shoe upper patterns and, for manufacturing of cutting dies, shoe lasts and sole moulds. CAD/CAM software is a PC-based system, which is made up of program modules. Today, there are 2D and 3D versions of CAD/CAM systems in the shoe industry.

Computer aided design was introduced in the shoe industry in 1970s. Initially it was used primarily for pattern grading. It enabled manufacturers to perform complex grading relatively easily and quickly. CAD systems today have been developed with a much wider range of functions. Logos, textures and other decorations can be incorporated into product designs of both the uppers and soles to help reinforce branding on all areas of the model. It automates routine procedures, increasing speed and consistency whilst reducing the possibility of mistakes. CAD data can now be used effectively for a wide variety of activities across footwear manufacturing business. CAD/CAM generates data at the design stage, which can be used right through the planning and manufacturing stages.

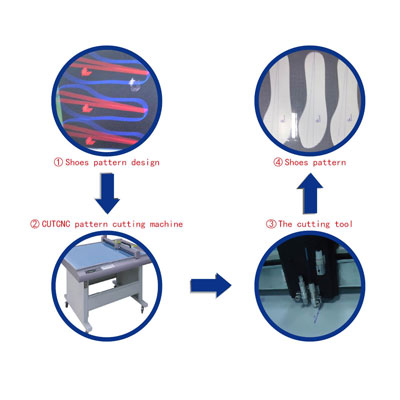

CUTCNC[CUTCNC?:cutting machine sample maker manufacturer] offer Saike shoes[shoes?:shoes paper pattern cutter] grade and design system, is one of the CAD/CAM in the footwear industry software. And CUTCNC shoes pattern cutting machine[cutting machine?:CUTCNC sample maker cutting machine] can cut the all the design.