This guide will explain everything you want to know about cardboard boxes, from how to make your own cardboard box to how the actual corrugated board is made before it becomes a corrugated cardboard box.

If you open a carboard box, and lay it flat you will begin to see how a cardboard box is made. This is kind of showing it reverse but it illustrated just how a cardboard box needs to be made.

To make a cardboard box you need a sheet of corrugated cardboard (called a blank), this blank needs cuts (slots) made to create the top and bottom flaps (lenght and width) you then need to make the creases to allow the box to fold at the flaps.

You will also notice a tab at the end of the box this is called the glue flap and as the name suggests is used to glue the box together.

So if you want to make a box size 430x300x300mm first you need to have a sheet of cardboard cut to the correct size

Lenght + Width + Lenght + Width + Glue Flap

17" + 12" + 17" + 12" + 2" = 60 Inches

To calculate the Width of the board you need to add the height of the box + width of the box.

Height + Width

12" + 12" = 24 Inches

So you need a sheet of board 60" x 24", once you have cut your board to size you then need to make the slots and creases to make the flaps, measuring out your board and making the cuts (slots) to fit.

Cardboard boxes are made from corrugated board, Corrugated board is generally made of three pieces of paper bonded together with a starch adhesive. The two outer layers (liners) remain flat however the middle layer of paper is made wavy (known as fluting) this gives the product its strength and is now called corrugated board.

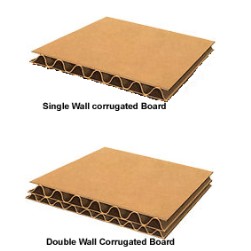

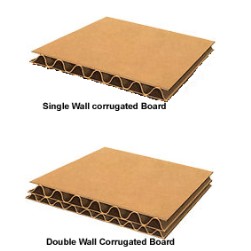

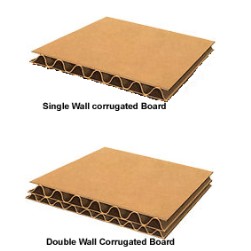

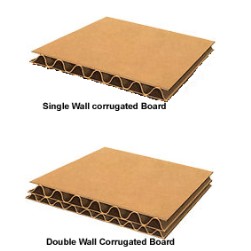

The most common types of corrugated board are single wall, which uses three pieces of paper to make it with the middle layer being the fluting (wavy). There are also double wall boxes these are made up from two single walled layers, so you have 3 paper liners sandwiched with two sets of fluting. (see diagram)