After the initial or standard pattern has been produced, a set or series of patterns have to be made.

After the initial or standard pattern has been produced, a set or series of patterns have to be made.

Every pattern in the set must reproduce the features of the standard, and in measurement be adaptable to the lasts or scale of measures for which the set is intended. The method selected to do this should be simple, yet adaptable to the various needs of the trade. In scaling or grading, the various parts of the standard such as vamps, etc., the difference between the length-line of the last and the distance round the last should be fully understood. The length of the last, on the size-stick plan, is measured by taking the shortest distance through the last, and in grading parts the ratio of the part to the original or standard last should be strictly maintained. If an imaginary cut be made through the last, then the relation of the proportion to the length of the last, or the distance round, may be remembered by noting that parts measured in their entirety on this imaginary axial line must be proportioned to the length of the last. Parts that start on the axial line, but do not continue throughout their length, should be ratioed to the length of the standard pattern, which represents the distance round the last. This is an important point to study if the desire be to make the shoes[shoes?:shoes paper pattern cutter] or boots made from the patterns graded, like the original or standard boot cut from the standard pattern. The diagram, Fig. 148, will assist the understanding of this point. The line AB is the length-line of the last, and therefore from what has been said it follows that the vamp-height or depth CD, and the golosh depth EF, would be regulated by the proportion it is of the line AB. The vamp-wing V would, on the other hand, be ratioed not by the length-line AB, but by the distance round the last from A to B, corresponding to the length of the standard pattern without the lasting over allowance. To put the parts affected in tabular form, it would be* If men's work, mark 4/9 in each side of the gusset central line, t Seven-ninths of an inch over one-fifth of the instep girth is recommended.

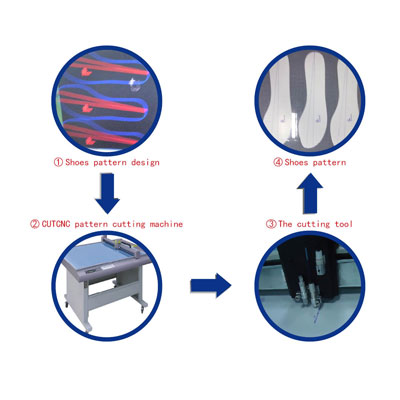

CUTCNC[CUTCNC?:cutting machine sample maker manufacturer] offer shoes paper[paper?:paper sample maker cutting machine] pattern cutting machine[cutting machine?:CUTCNC sample maker cutting machine], cut the grading pattern of shoes, make the sample and do short run production. Can make the pattern grading automatically with our Saike shoes pattern design[pattern design?:pattern design cutting machine] software.